Trumpets or so called ‘velocity stacks’ etc are not only a nice looking add-on to your carb equipped engine, they make a huge amount of difference to your power curve depending on which type-shape & length you choose.

Ok so let’s start with how air flow through the carb works:

As the inlet valve opens; air at atmospheric pressure rushes through the trumpet-the carb-the manifold and finally through the cylinder head and into the cylinder. This cycle creates a 'pulse' and once the valve closes the pulse will change direction & go back through the carb.

A trumpet is needed to smooth out the pulses and help keep the air flow direction constant.

Remember, air is not really sucked into an engine. It is ‘pushed’ in by the natural pressure of air (14.7PSI at sea level). The displacement of the piston simply makes room for the air to go.

The displacement creates a pressure change & thus ‘airflow’ is made, This can be used to our advantage when selecting trumpets for a given application…..

Some ‘inexperienced’ shops will tell you that you only need a long trumpet for max low end torque & short length for maximum power- these people demonstrate a very basic level of ‘pub chat’ knowledge. Yes it may be occasionally seen that long trumpets give more low end, and top end is gained by using shorter trumpets, but the main reason we use different length trumpets is to ‘pulse tune’ the engine and the trumpet length is just a function of the total length of inlet tract- A long trumpet on a already long inlet length will do nothing for power!

Pulse tuning is a natural phenomenon & fact. The Pulse occurs when the inlet valve opens; this creates air movement & thus a ‘sound wave’. This sound wave moves very fast from the inlet valve to the end of the trumpet mouth, once it has reached the end of the trumpet it reverses & starts to move back towards the inlet valve carrying air and fuel back into the engine (thus improving the volumetric efficiency of the engine) kind of like forced induction.

Remembering that the airflow into the engine is continually ‘pulsing’ at different speeds due to the opening & closing of the valve, maximum pulse effect will be found at different RPM’s for different engines & ‘total’ length of the inlet tract.

There is no minimum or maximum length of trumpet for any given size of carb & shops that say ‘This is a ideal length trumpet for X mm carbs for all round performance’ are completely incorrect & no doubt trying to sell you something that you don’t want!

There are so many factors to take into account when selecting trumpets- Cam duration-Cylinder port shape and length, Inlet manifold length/shape, Cylinder capacity, Max rpm, How much room within the engine bay- What the car is used for etc and so on and so on. Trumpet length has nothing to do with carb diameter alone.

A downside of pulse tuning is that when you find a gain at a certain RPM, you WILL also get a loss at another RPM- If the loss is found at a ‘un-used’ rpm for your application (typically mid end for race cars & low end for rally etc) that your happy, but this does tend to take a few hours at a rolling road to achieve.

Ok so now you should understand the importance of using the correct length trumpet for you application.

Lets look at using ‘mesh’ screening & air filters etc.

Coverings are again as variable as the trumpet length itself! (But are generally chosen primarily for there appearance).

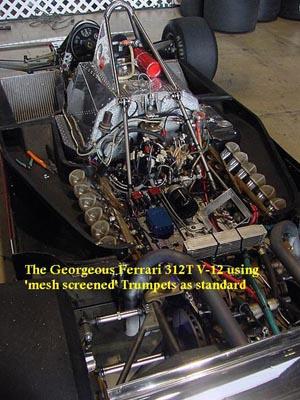

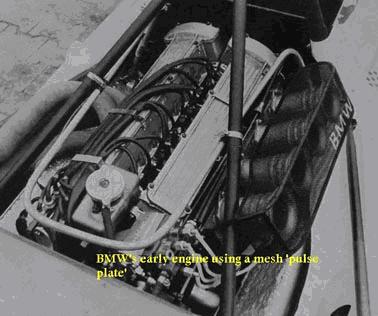

Contrary to popular belief, Mesh coverings are not a modern 'bling' invention, but have been used by top manufactures all over the world for many years (namely the gorgeous Maserati 300s which uses triple weber Carbs, BMW's ,Many Ferrari's including the 312s Single seater and the 500F2 and many more) when using carbs or throttle body’s for the advantages the mesh screening gives over open ended trumpets or filters.

People who say ‘stay away from mesh screening’ are wrong- there is no if and but about it, they do not 'cap' peak power (actually they can increase low range torque- reduce spit back & improve drivability!) if anyone can supply me with genuine test reports (real ones, not some un-realistic Rolling road chart obviously created in Photoshop) proving otherwise I will eat my hat.

Mesh screening is an excellent compromise between not using air filters (yes there are an awful lot people who run the engine with open ended trumpets and no filters in the hope of finding more power) & using filters.

People who run their engines without filters will be aware that the engine will not last as long as a engine with an air filter-BUT if a stone/leaf etc was to get drawn into the engine through the open trumpet then this could destroy the engine instantly & cost a lot more than a general rebuild! In short-Do not run your engine on a open road using only open ended trumpets unless you are a member of the AA & have lots of ££!

The airflow through mesh coverings of course does depend on the quality of the screening itself- I’ve seen some cars with 'cheap' -‘tea strainer’ type mesh, these give no performance gains at all (plus they don’t even look good!). Quality Mesh or Filters can have a added bonus to air flow by utilizing the pulse tuning effect- once the air has passed into the carb it can gain pressure by ‘bouncing’ back of the screening (This is an effect which is commonly seen when using ‘plate backed’ air filters (see pic) & can have a great effect on performance- It is sometimes referred to as ‘air anti reversal ratchet’ and this can also reduces ‘spit back’.

Picture of a K&N ‘Plate backed’ Air filter, these can provide power gains from ‘pulse tuning’.

Keeping the air direction change to a minimal will help keep the flow through the carb constant but the added turbulence of the air passing through the mesh screenings can also help the atomization of the fuel before it enters the cylinder- Max 'airflow potential' will be reduced but the result can be better drivebility.

We always recommend using air filters for general road use, they may seem like they are a restriction to flow, but in fact on one of our own 150bhp rally cars we saw only a reduction of 3Bhp at 6800rpm when using a filter, well worth the compromise

If you need any advice on Trumpets please don’t hesitate to contact us.

(Various pictures displaying F2 Manufactures using mesh screenings)

This Article is written completely by XLR8. It is our property & is protected by copyright 2006. Any unauthorized copying is strictly prohibited.